About us

Rebrado is a workshop for the manufacture of resin scale models kits since 2002. All products are developed and manufactured in St. Petersburg, Russia. The model kits are produced using our original technology, which makes them not like the others. We only produce clean castings, so our products do not require additional processing before painting or assembly (except for disconnecting them from the sprue). All castings are easy to paint, they have a paper texture which allows to paint the model without soil, use markers and even pencils for painting. Parts can be placed on large sprue systems up to 200*280mm in size, which is not done by any of the manufacturers of the resin model kit in the world. The use of such sprue systems significantly reduces the cost of the entire product, the kit has a much more attractive appearance compared to the classic resin model kits parts, as well as simplifies the work with the parts. Connecting the sprues to the parts is carried out in such a way that would prevent damage to the part when it breaks off from the sprues. Batches can range from a few dozen to several thousand sets, with a capacity of up to 150 sets per day. We also offer a much lower cost of pre-production compared to similar products made of conventional granular plastic. Depending on the number of copies and the material of the castings we use different types of forms, from silicone to polyurethane. We use only time-tested materials, all of them were carefully selected by us, are perfectly suitable for modeling and do not change their properties over time. Plastic is perfectly processed if necessary. You can drill it, cut it, skin it, scratch it, and it won't break or crack. The material is perfectly glued with cyanacrylate glue, resistant to solvents, well-proven as toy reducers, works great with different types of lubricants. Castings can be painted by spraying paint on the mold or the classic method of spraying on the casting, as well as by adding pigment to the plastic. For the manufacture of rubber-like products, a material with different hardness and color can be used. Also, castings can be made of a durable foam material, which is relevant for radio-controlled models of aircraft. This material will be foamed inside and smooth on the outside, which makes it ideal for coloring or transferring images. Transparent parts can be rubber-like and hard as plastic. Any transparent castings can also be made of colored material. To get started we accept concepts (3D files, images) and physical prototypes. Any prototypes can be made with high detalization up to 40 microns. And please note, this is the detalization of the milling machine, which is much clearer than the detalization of a 3D printer, where the details become blurry at such small size.

Our products are not intended for children.

Please note that all photos in the gallery "Our products" are made from serial castings produced in our workshop and meet the actual quality of the products produced. In the gallery "Models built from our kits and photos of the production process" you can see how we create models and fully built models from our kits.

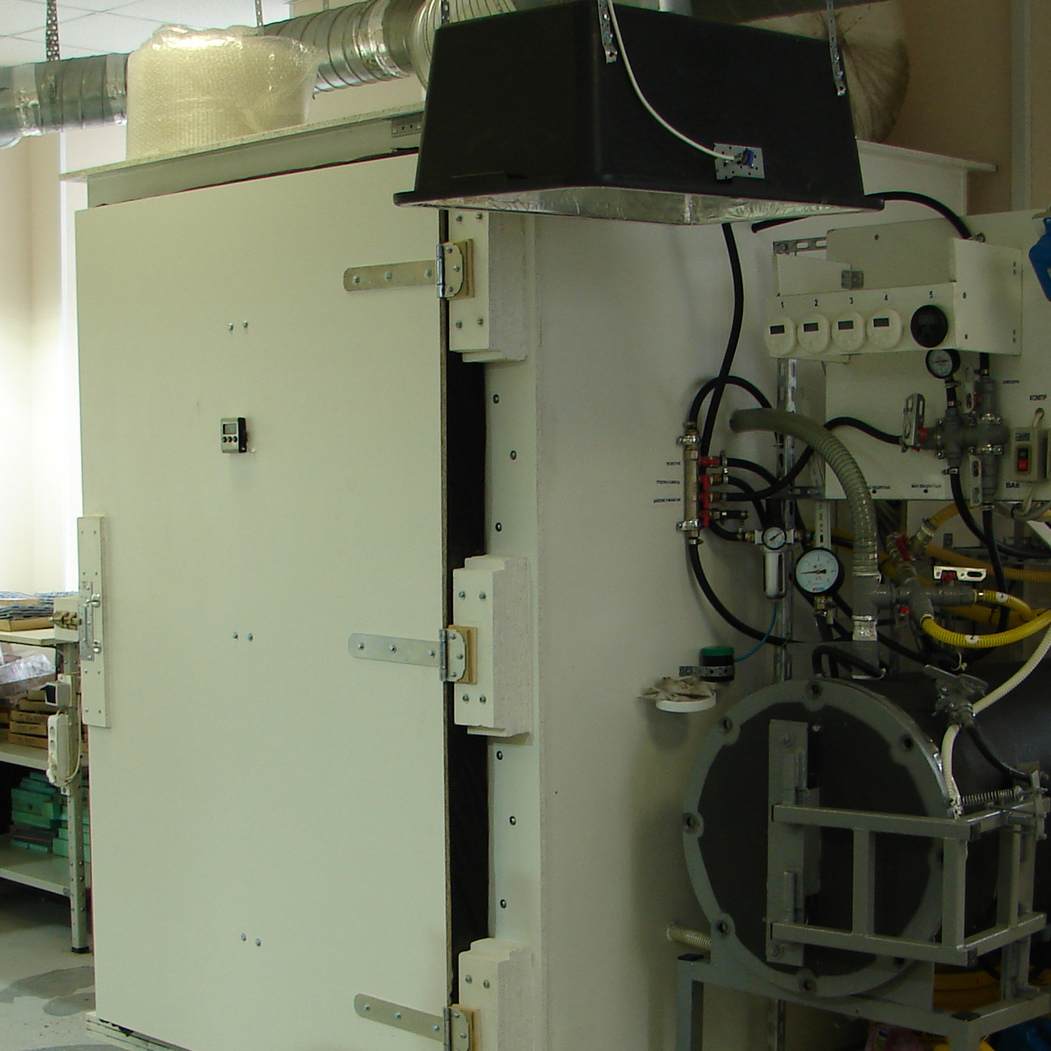

Our manufacturing: